Iain Oswald

Well Engineering Management and Assurance.

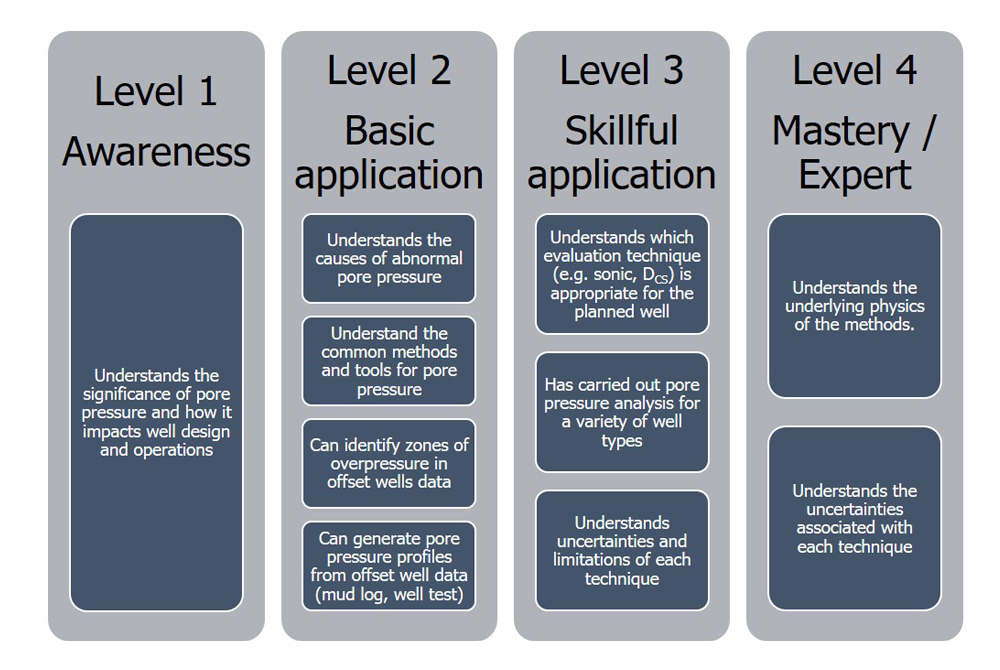

First and foremost I am an engineer who is passionate about problem solving and thinking conceptually. I have 24 years of international expertise within the sphere of designing and constructing all types of wells. For the last five years I have focused on the support mechanisms that can be put in place to help drilling and completion engineers make the right decisions.

I chose the oil industry in 1992 after graduating in Mechanical Engineering from University of Strathclyde. I started as a design engineer for a wellhead manufacturer. After four years I returned to university and completed an MSc in Petroleum Engineering at Heriot-Watt University. From that point, my career has been focused on a blend of well engineering, operations and supervisory experience, including 18 month in production engineering. Starting my career in the North Sea with semi-submersibles in the mid-nineties, I went on to spend a significant period of my career running jack-up rigs in the Middle East, before taking on global roles that covered all well types from Mexico to Malaysia.

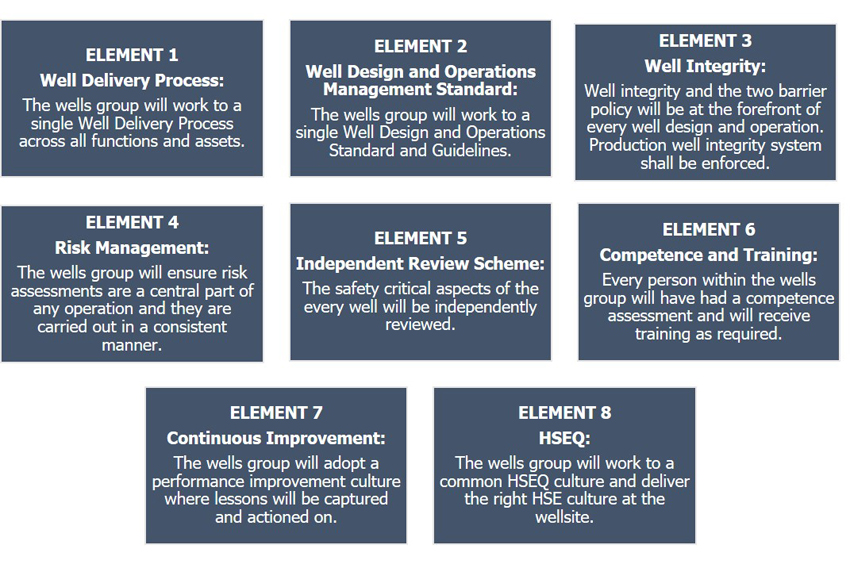

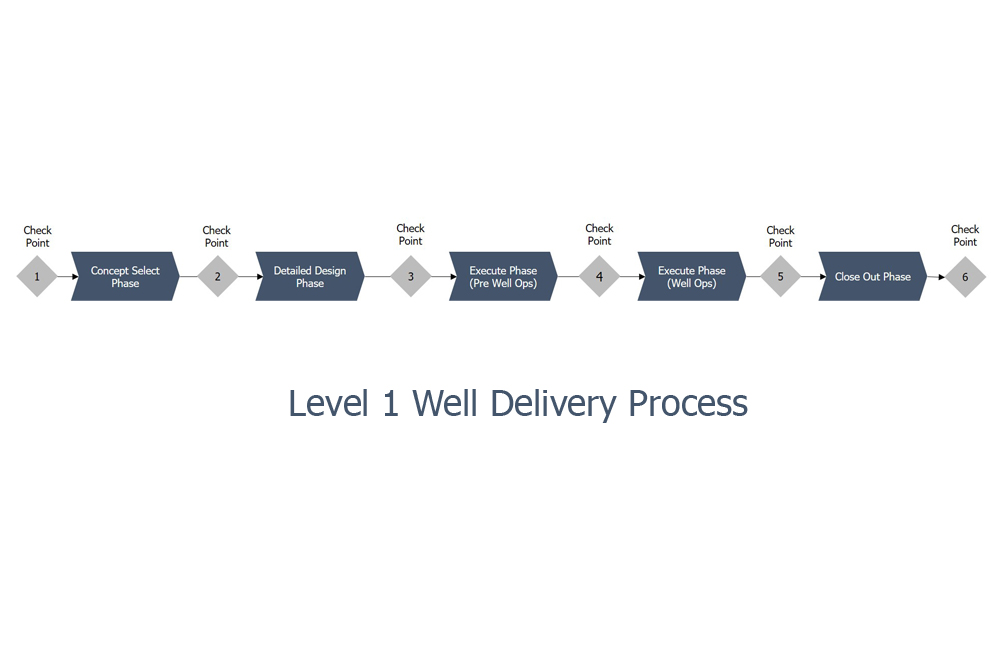

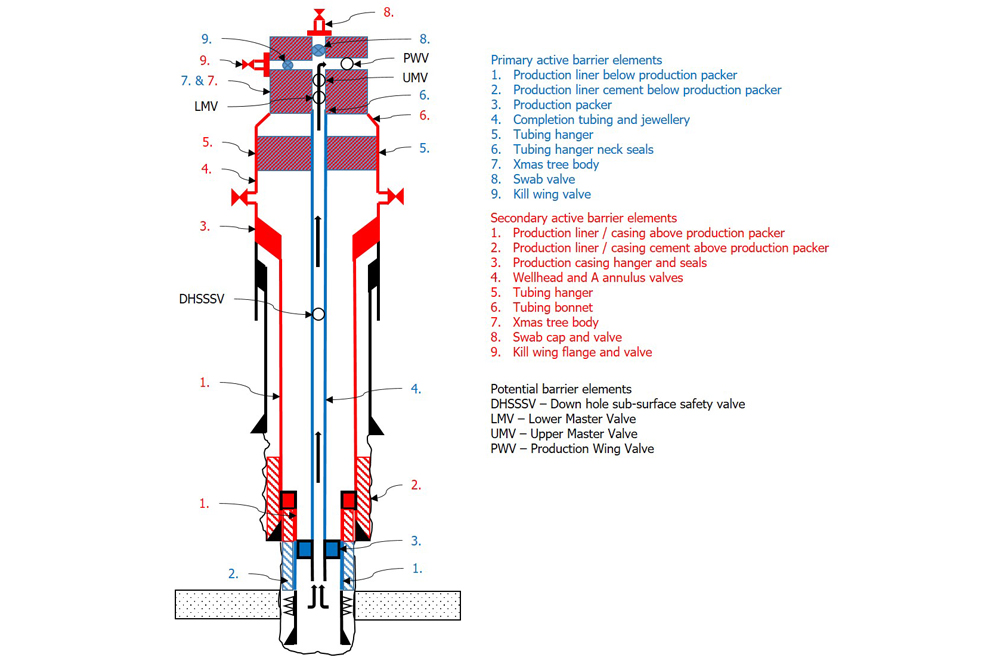

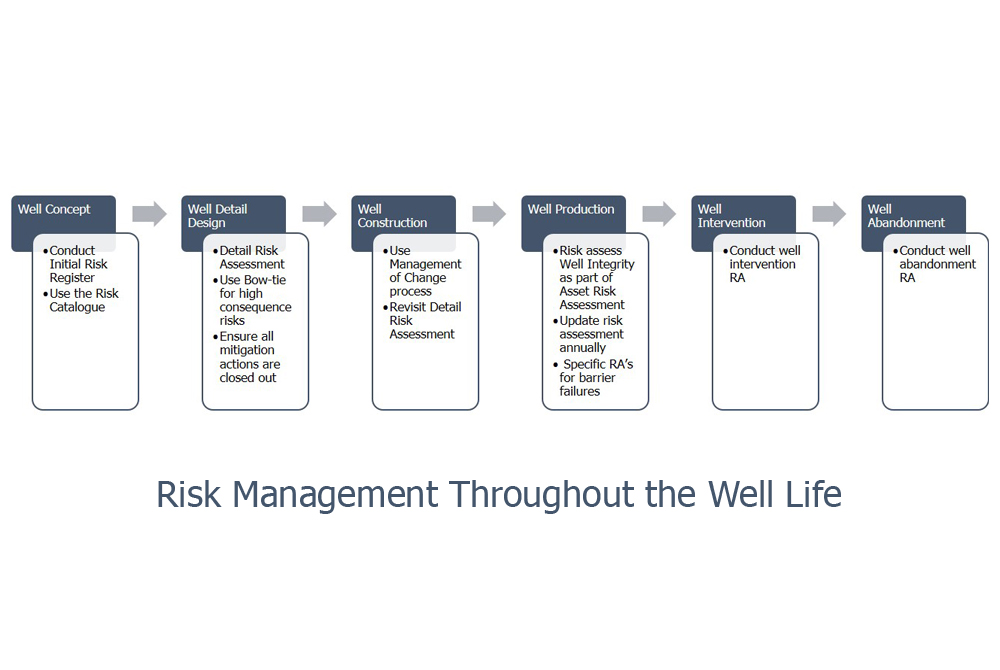

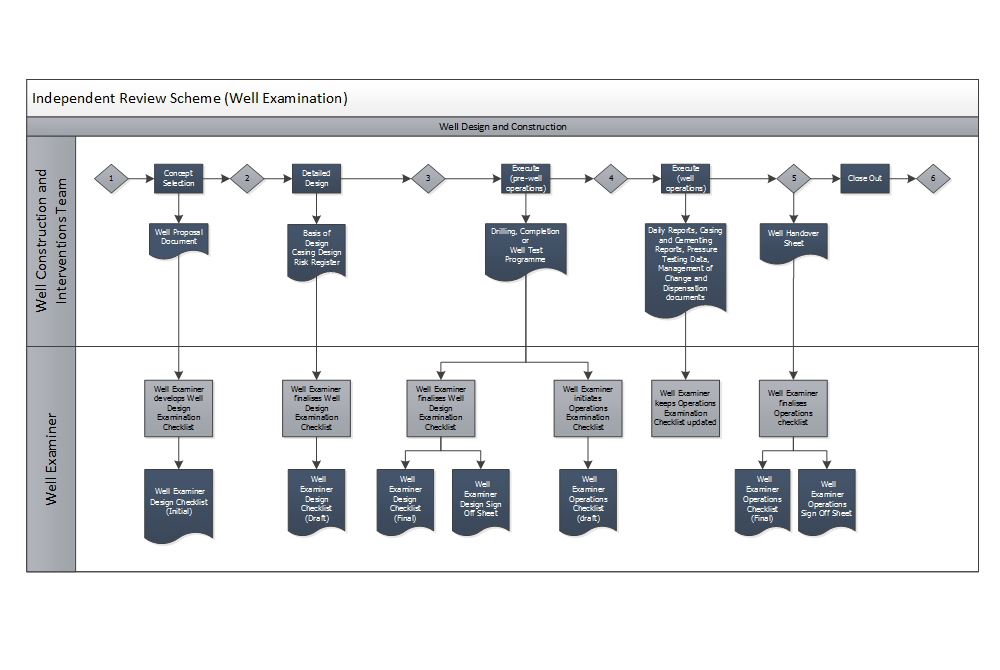

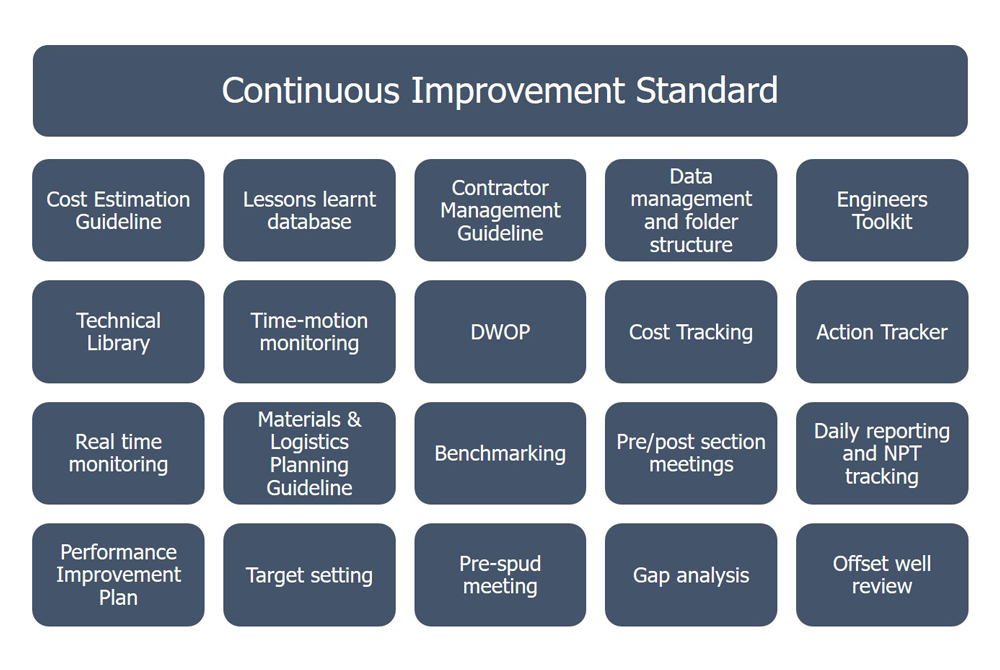

I then moved in to Well Engineering Management and Assurance. The importance of well engineering decisions was publicly aired during the BP Macondo disaster in the Gulf of Mexico in 2010. Governments, regulators and operators took a closer look at engineering decision making and the role of well management systems. I have spent the last five years focusing on the framework of processes and procedures that ensure a drilling organisation can fulfil all its tasks and achieve its objectives safely and efficiently.

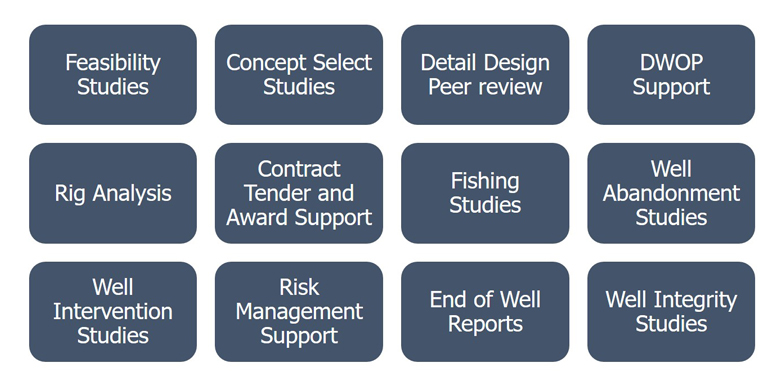

With 24 years of well engineering experience in offshore and onshore well design and operations in various roles, from night drilling supervisor to well engineering manager, I can offer advice on all aspects of well design and operations.

My passion is engineering and problem solving. However in the last five years I have enjoyed the guidance and mentoring aspect that comes with well assurance and management. Designing and constructing a well requires people from different departments, ready to communicate and cooperate to get the job done. I have worked with several drilling and subsurface teams, to ensure an integrated multi-discipline approach during well delivery.

For more detail on my career, please visit the Experience section.

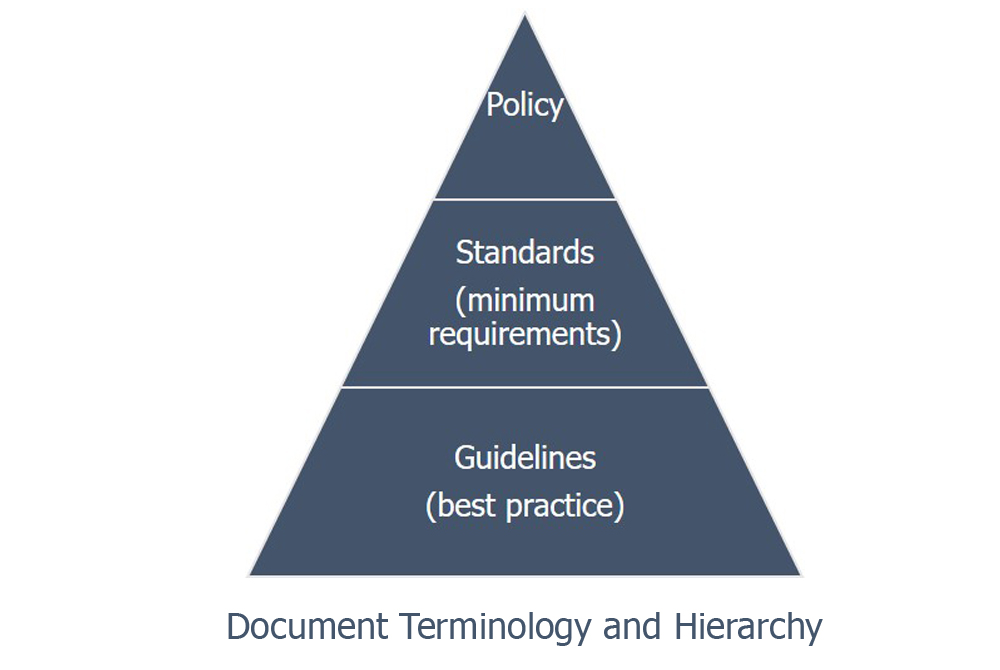

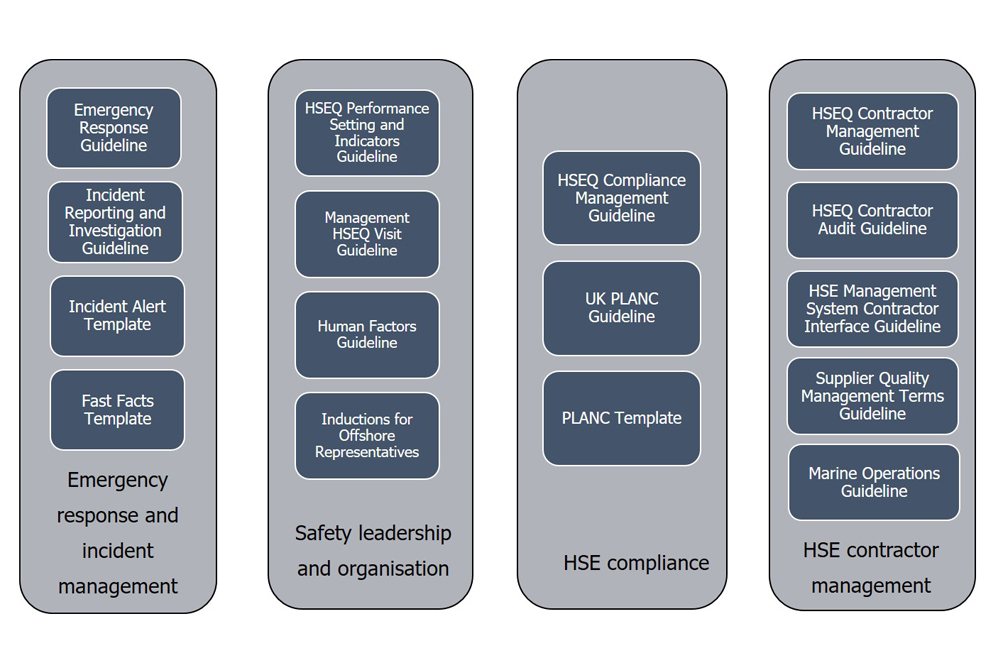

The vision of Oswald Well Engineering is to offer client support and advice, to help ensure the correct well engineering decisions are made. This support can be through advice on well management systems in order to bring the best out of their organisation. Whether there is a blank sheet or a partial system in place, Oswald Well Engineering can offer bespoke well management system support, starting from individual documents to a complete system. It is very important that the well management system is ultimately owned and managed by the engineers using it.

Alternatively, Oswald Well Engineering can offer direct support in projects to find the best possible technical and commercial solution.